Reliable Electrical Solutions

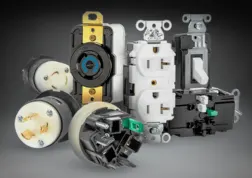

Brands you can trust for all your commercial, industrial, residential and utility electrical product needs.

Featured Products

Hubbell Canada is committed to its digital transformation strategy, aiming to provide a unique and valuable experience to its partners and stakeholders. The company understands the importance of listening to its customers and is continuously improving its digital tools to deliver information efficiently and in the preferred format. Furthermore, Hubbell Canada is expanding its French content to cater to customers who prefer to access information in their preferred language. With a focus on trust and dedication, Hubbell Canada is steadily enhancing its digital capabilities.

KEVIN MALLORY | Vice President & General Manager