115-1000A, Running Rail Connector, 1000-1250 kcmil Cu, for 115# A.R.E.A. Rail

Brand:

Burndy

Catalog ID:

115-1000A

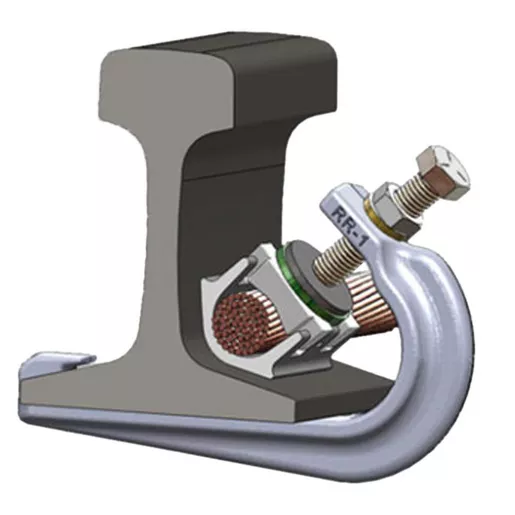

CPI Running Rail Connectors are designed as a permanent connection for copper conductor to a variety of rails used in Heavy Rail Mass Transit systems. Constructed with a heavy duty aircraft-quality steel spring member, copper cable nest, indentor, hex head bolt and locking nut.

- No drilling in rail or need to weld conductor to the rail!

- Rail is not subjected to warping by excessive heat or weakening by drilling

- Labor saving - installation time can take as little as 10 minutes per connection

- Fewer rail connections required due to large conductor capacity (Single conductors up to 1000 kcmil, Dual conductors up to 750 kcmil)

- Large conductors can be bent away from the rail after installation without the risk of damaging the connector

- The clamp is an active spring applying a consistent force on the conductor ensuring a positive connection through heat cycling and train vibration

- The J-shaped spring member of the connector helps overcome loosening issues, problems associated with harsh train vibration, by flexing rather than breaking - a static-type connection doesn't have this resiliency and could crack under prolonged vibration

- Consistent spring pressure prevents moisture and contamination from seeping into the connection

- All copper components are tin plated and steel components are galvanized

Product details

General

Catalog Number

115-1000A

UPC

621945675445

Conductor Related

Conductor Range

Rail Size & Type: 115 lb AREMA, 119 lb AREMA

Conductor Size Range: 1000 kcmil - 1250 kcmil

Conductor Size Range: 1000 kcmil - 1250 kcmil