A Cup Full of Beads

Find out how a Hawke Desiccant Breather can extend the life of your machinery with just a cup full of beads. Learn more today.

Here is a glimpse of HAWKE’s solutions for the different Markets. Try out some Hawke Solutions.

Here is a glimpse of HAWKE’s solutions for the different Markets. Try out some Hawke Solutions.

A quick look through the various markets we are equipped to cater. See the Hawke markets.

A quick look through the various markets we are equipped to cater. See the Hawke markets.

Here is a glimpse of HAWKE’s solutions for the different Markets. Try out some Hawke Solutions.

Here is a glimpse of HAWKE’s solutions for the different Markets. Try out some Hawke Solutions.

A quick look through the various markets we are equipped to cater. See the Hawke markets.

A quick look through the various markets we are equipped to cater. See the Hawke markets.

Written by Olivia Serrage on March 23, 2017

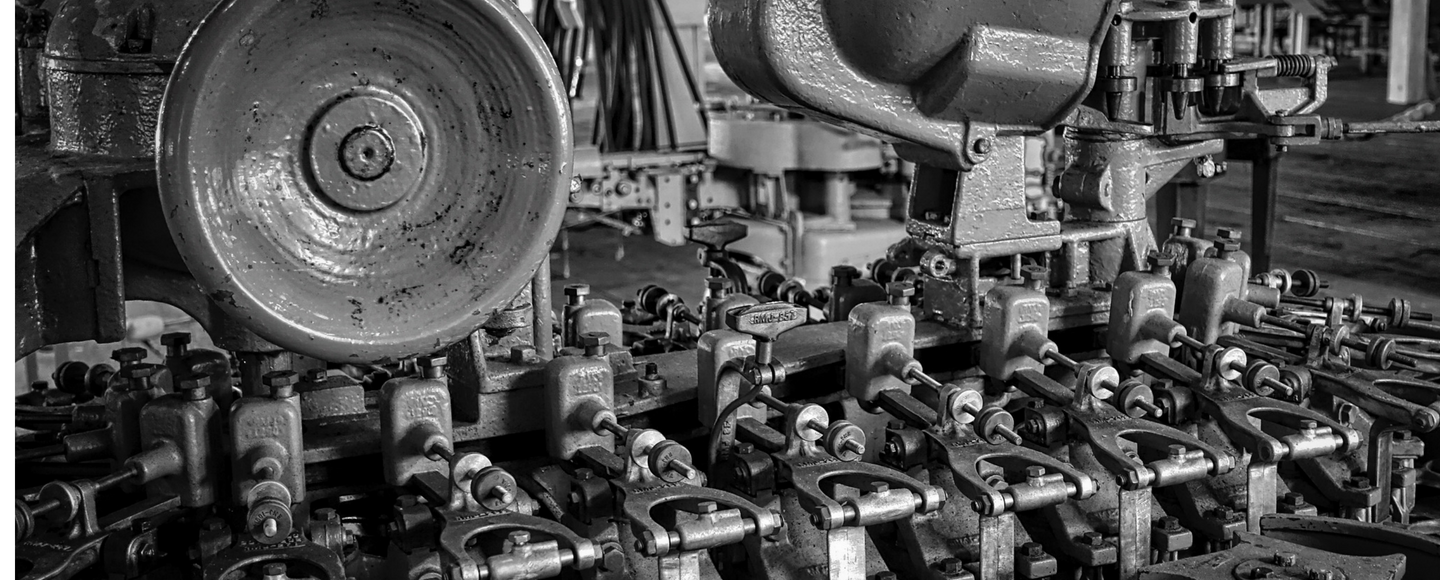

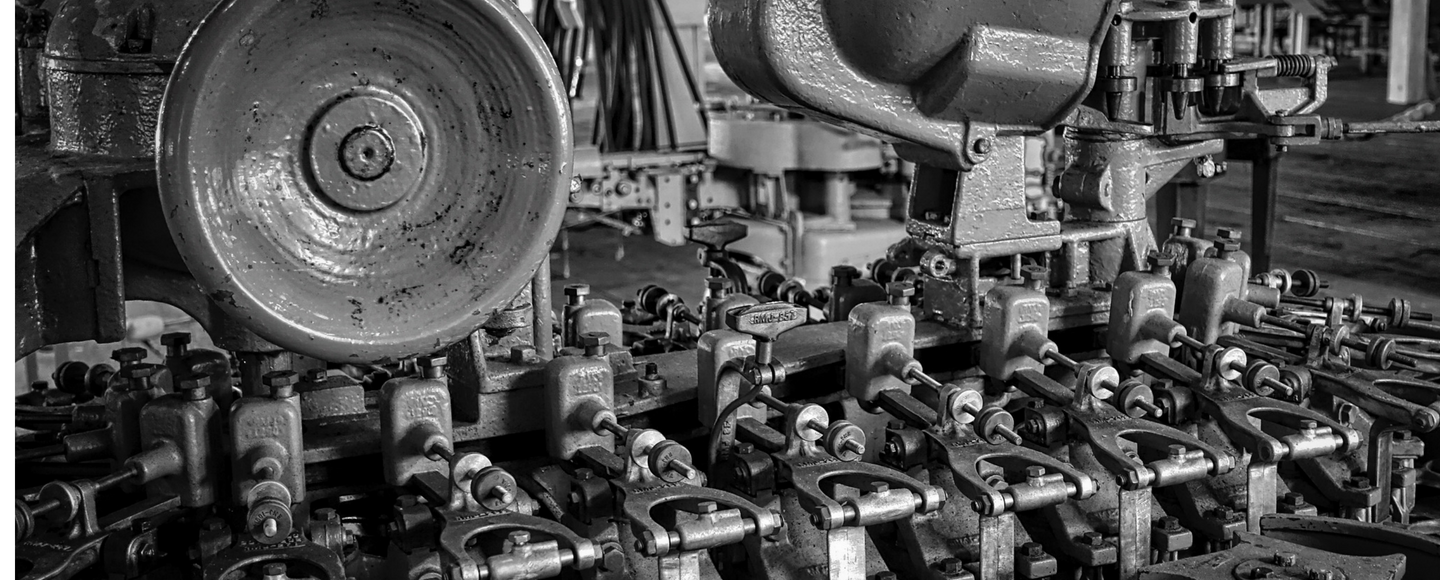

The biggest cause of machine break down is from machines breathing in dirty, wet air. Over time, the intake of this air leads to the abrasion, erosion, adhesion and fatigue of your machinery, causing it to break down much more frequently than it should do.

Breathers prevent machines from taking in this air, expanding their lifespan and improving their reliability. A small investment in a breather at the start of a machines life will save you a great deal of costly downtime later.

Sign me up to receive the latest posts from the Hawke International Blog to my email.