AUSTDAC LONGWALL MINING SYSTEM

LONG DISTANCE SIL 3 SAFETY SYSTEM

Austdac have been supplying longwall systems for over 20 years with systems all over the world. Major international installations in USA, Australia, UK, Russia and South Africa.

The Austdac Longwall communication and monitoring system is adaptable to meet any customer design criteria. Our system has been designed and tested to suit your longwall, providing better solutions for your environment and layout.

Our emergency stop system is internationally accredited to SIL3 safety rating by TÜV. It is designed to SIL (Safety Integrity Level) 2 or 3 if required. The safest and most reliable emergency stop system on the market. The unique SILBUS transmission method allows for the combined transmission of high integrity SIL3 longwall emergency stop signals with monitoring and control signals for gas monitoring as well as analogue values such as bearing temperature and vibration.

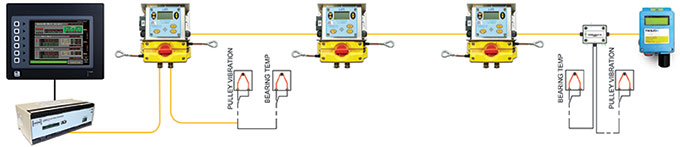

All SIL 3 safety and standard digital inputs are down line powered. No external power required along the length of the longwall.

The control and monitoring transmitters in the pullkey are system powered, meaning no external power need be connected along the length of the longwall.

FLEXIBLE & UNIQUE SYSTEM

- Our unique transmission system allows analogue and digital signals to be transmitted and received on a 2 wire cable. The system is totally flexible to accept both digital and analogue inputs (e.g. full switch monitoring and gas monitoring, temperature monitoring on the longwall on one cable)

- New speech message transmission can transmit up to 255 pre-recorded voice messages

- Gives accurate speech messaging of fault status of longwall or outbye conveyors

- Monitoring of analogue and digital signals ensures complete monitoring update of all field devices along the conveyor with rapid update time. Ensure downtime is minimised with fast diagnosis of the reason for belt stoppage. Every switch is monitored.

- Interface to all PLC and DCS systems.

- Up to 128 signals either digital or analogue per side of conveyor.

- Transmission system has high CMRR (common-mode rejection ratio) ensuring noise immunity preventing noise being induced on the system.

- Long distance transmission over 10km.

- The only long distance transmission system with SIL3 safety rating as accredited by TUV.

single cable solution for longwall installations

The Austdac pullwire cable has been specifically designed to operate as the pullwire medium of the emergency stop circuit but also contains the electrical conductors for the emergency stop system and monitoring and to activate a full length of conveyor pre-start warning system.

One cable solution means SIL3 rated emergency stop system, digital inputs such as belt wander, chute full signals and analogue values such as bearing temperature, vibration monitoring as well as conveyor pre-start warning on the same cable that is used as the pullwire. Huge savings in material and installation costs.

- Slip ring plug and socket connection provides simple installation with rugged reliable cable connection

- One cable solution for switch monitoring, analogue monitoring, pre-start warning and voice communication

- Voice communication system easily connected to surface control room

- One cable solution for BSL and AFC

- Pre-start alarm is fully monitored

- BMA (telephone) modules have LCD display giving full condition monitoring of the unit

- Austdac pullkey has been fully assessed to a SIL rating and a performance level

- Full FMEA (Failure Mode Effect Analysis) carried out for all modules