Panelboard Solderless Lugs,Type: ABV-500 -4 AWG, Al/Cu Rated

Brand: Connector Mfg. Co. (CMC)

Catalog ID: 4ABV-500

*Now Rated for Flex Cable*

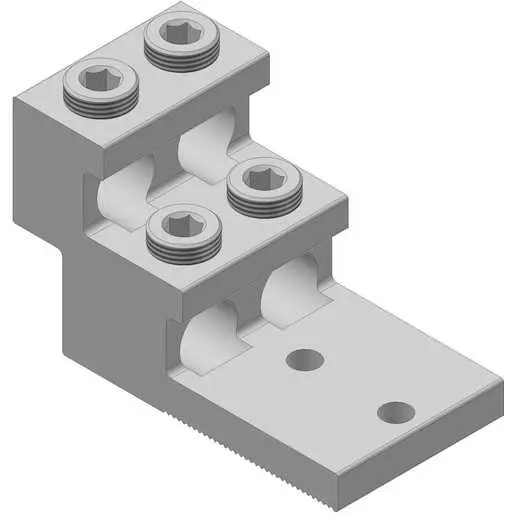

Panelboard Solderless Lugs,Type: ABV-500 -4 AWG, Al/Cu Rated. The unique ridges formed on the bottom of the contact surface are designed to provide contact points for an electrically secure joint of the lowest resistance for current flow. The screws used to clamp the conductors are designed to extend beyond the barrel sides of the conductor to allow a better, more secure compression of the conductor. This design spreads the conductor trands to help dissipate heat, and improve its pull-out safety features and capabilities.The design of the wire way provides optimum transfer of current, creating a straight line flow through the connector for the least possible path of electrical resistance. A positive wire stop is also provided.90° C Rated (486B Listed). UL listed and CSA certified.

The unique ridges formed on the bottom of the contact surface are designed to provide contact points for an electrically secure joint of the lowest resistance for current flow;The screws used to clamp the conductor are designed to extend beyond the barrel sides of the conductor to allow a better, more secure compression of the conductor. This design spreads the conductor strands to help dissipate heat and improve its pull-out safety features and capabilities.;The design of the wire way provides optimum transfer of current creating a straight line flow through the connector for the least possible path of electrical resistance. In addition, a positive wire stop is provided.;For installation,CMC® recommends the use of an insulated Allen wrench.;Electro tin plated to provide low contact resistance and protection against corrosion

- The unique ridges formed on the bottom of the contact surface are designed to provide contact points for an electrically secure joint of the lowest resistance for current flow

- The screws used to clamp the conductor are designed to extend beyond the barrel sides of the conductor to allow a better, more secure compression of the conductor. This design spreads the conductor strands to help dissipate heat and improve its pull-out safety features and capabilities.

- The design of the wire way provides optimum transfer of current creating a straight line flow through the connector for the least possible path of electrical resistance. In addition, a positive wire stop is provided.

- For installation,CMC® recommends the use of an insulated Allen wrench.

- Electro tin plated to provide low contact resistance and protection against corrosion

General

Catalog Number

4ABV-500

Material

Aluminum

Type

Bolted Lugs & Terminals

UPC

192663018888

Dimensions

Dimensions

4.9 in x 2.5 in x 3 in

Height

3 in

Length

4.9 in

Thickness

0.5 in

Width

2.5 in

Conductor Related

Conductor - Copper Str Size Range

500 Kcmil-4 AWG